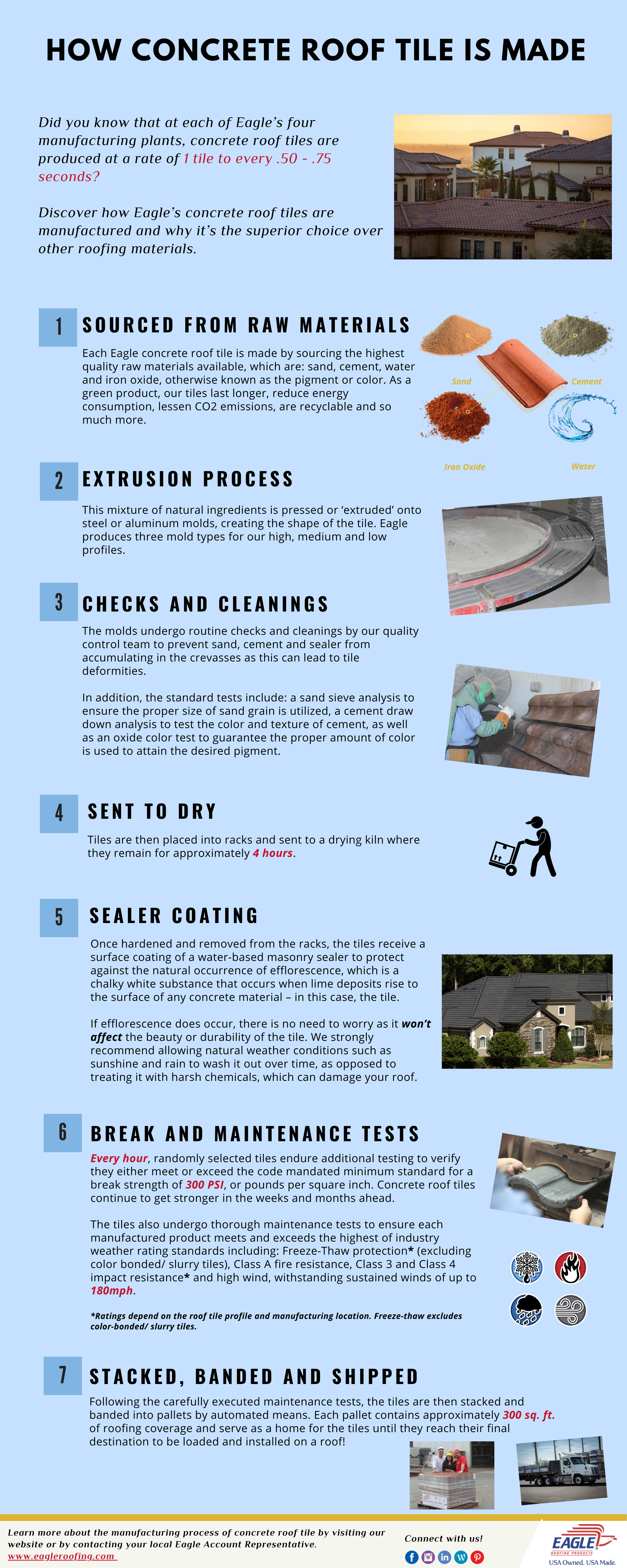

Discover How Eagle’s Superior Concrete Roof Tiles Are Manufactured

At each of Eagle’s four manufacturing plants, concrete roof tiles are rapidly produced at a rate of 1 tile to every .50 to .75 seconds. Each tile is made by sourcing the highest quality raw materials available, which are: sand, cement, water and iron oxide. This careful combination of ingredients is pressed onto steel molds, creating the shape of the concrete roof tile. These molds undergo routine checks and cleanings by a quality control team to prevent sand, cement and sealer from accumulating in the crevasses as this can lead to tile deformities.

The tiles are then placed into racks and taken to a drying kiln where they will remain for approximately four hours. Once hardened, they are removed from the racks and receive a surface coating of a water-based masonry sealer to protect against the natural occurrence of efflorescence. Every hour, randomly selected tiles will endure additional testing to ensure they either meet or exceed the code mandated minimum standard for a break strength of 300 PSI, or pounds per square inch.

In addition, Eagle administers vigorous maintenance tests to ensure that the tiles manufactured will meet and exceed the highest of industry weather rating standards including: Freeze-Thaw protection (excluding color bonded/slurry tiles), Class A fire resistance, Class 3 and Class 4 impact resistance and high wind, withstanding sustained winds of up to 180 mph.

Finally, the tiles are stacked and banded onto pallets where they will safely reside until they reach their final destination, to be installed on a roof, where they will remain for decades to come.